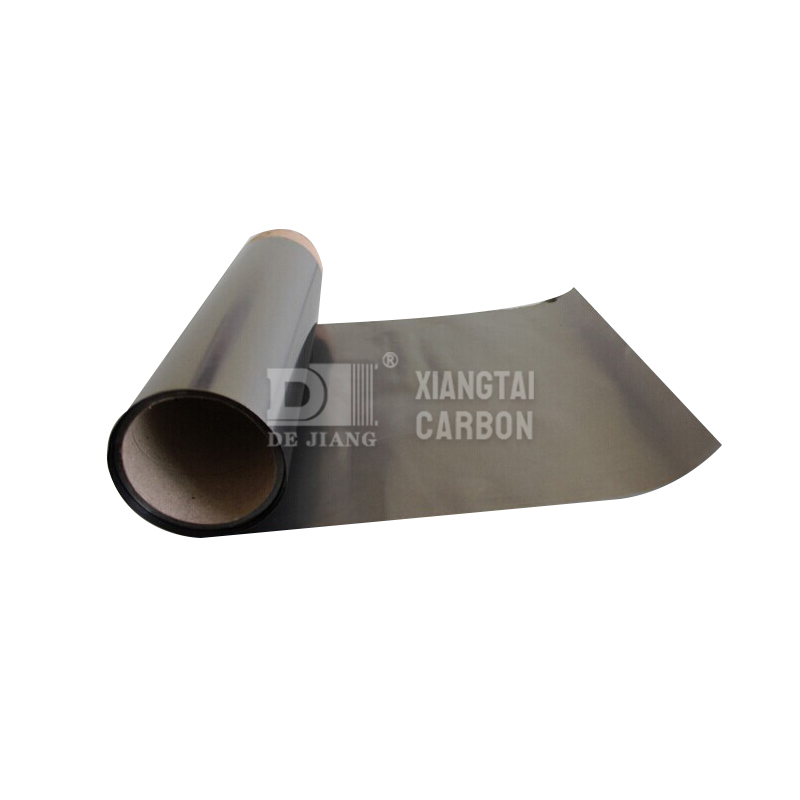

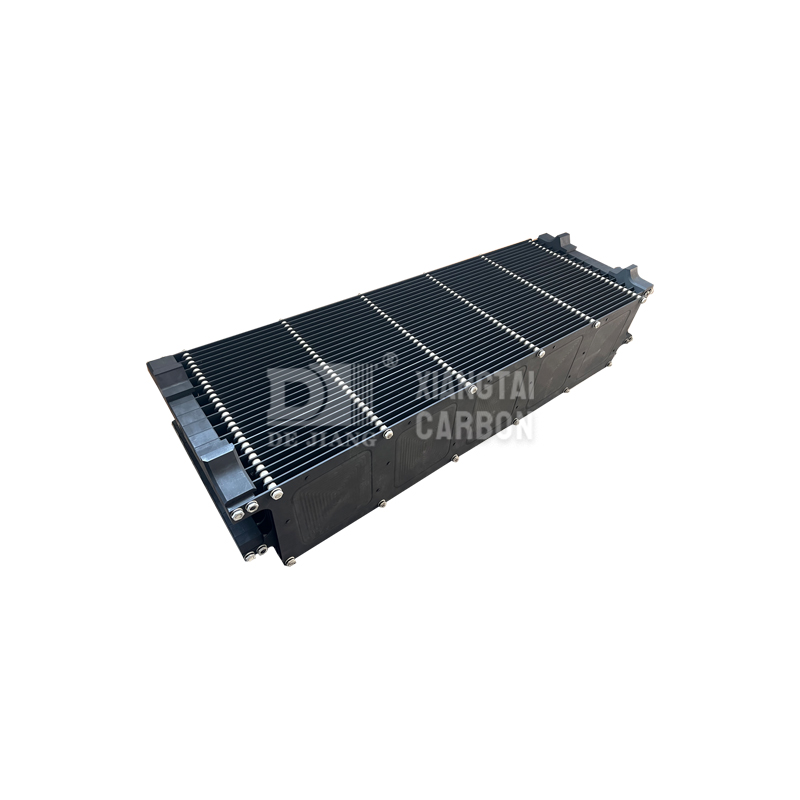

what are the characteristics of graphite electrode materials? Next,xiaobian will introduce you one by one.

1.Easy to polish;

Because the cutting resistance of graphite is only 1 / 5 of that of copper, itis easier to grind and polish;

2.Light weight;

The density of graphite is only 1 / 5 of that of copper. When the largeelectrode is used for EDM, it is more suitable for the use of large mold;

3.The loss is small;

Because there are C atoms in the spark oil, the high temperature causesthe c atoms in the spark oil to be differentiated, and forms a protectivefilm on the surface of the graphite electrode, which compensates for theloss of the graphite electrode;

4.Low cost;

Due to the rising price of copper in recent years, the price of graphite islower than that of copper in all aspects; for the universality of carbon in thesame volume, the price of graphite is 30% to 60% lower than that of

copper, which is relatively stable, and the short-term price is relativelysmall.

5.No burr;

After the copper electrode is processed, it needs technology to remove theburr, while the graphite electrode is processed without burr, which not onlysaves a lot of cost and manpower, but also simplifies the automatic

production;

6.Fast speed;

Graphite discharge is 2-3 times faster than copper, and the material is noteasy to deform. It has a significant advantage in the processing of thin ribelectrode. The softening point of copper is about 1000 degrees, and thedeformation is caused by heating. The progressive temperature of

graphite is about 3650 degrees. In comparison, the coefficient of thermalexpansion of graphite is only 1 / 30 of that of copper.