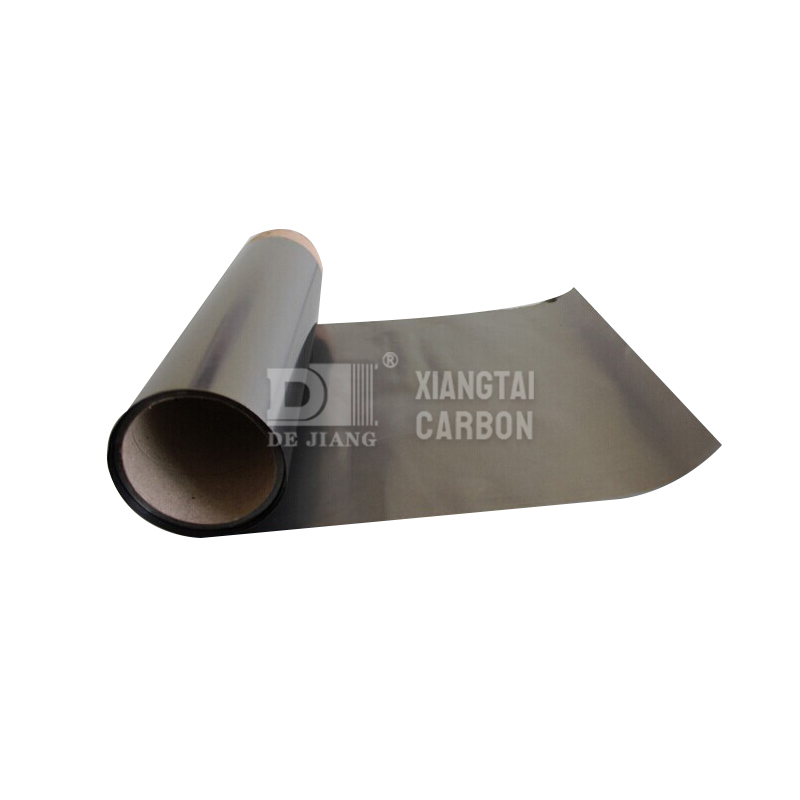

Natural flake graphite is also called natural crystalline graphite. Its shape resembles fish scale, so it is called flake graphite. It belongs to the hexagonal crystal system and has a layered structure. Natural flake graphite has complete crystals, thin flakes and good toughness. It has excellent physical and chemical properties, with good temperature resistance, self-lubricity, thermal conductivity, electrical conductivity, thermal shock resistance, corrosion resistance and other properties. Natural flake graphite is widely used in advanced refractory materials and coatings in the metallurgical.

Graphite powder is a non-metallic mineral material. Graphite powder has high conductivity and thermal conductivity, high melting point, good lubricity, plasticity and chemical stability. Graphite powder can be corroded by acid, alkali and organic solvents. Therefore, it is widely used in chemical, petroleum, metallurgy, casting, lubrication, sealing and other industrial fields.

Advantages of Graphite Powder

01Lubricity

Graphite powder is a kind of natural lubricant with good self-lubricating properties. Its advantage over Molybdenum Disulfide in the lubricating industry is that it will not produce a pungent smell at high temperatures. The lubrication performance of the composite varies with the scale size, and the larger the scale is; The smaller the friction coefficient, the better the lubrication performance.

02Thermal shock resistance

1. The smaller the elastic modulus of graphite powder, the better the elastic properties, the stronger the ability to buffer thermal stress, and the better the thermal stability.

2. The smaller the coefficient of thermal expansion of graphite lubricating powder, the higher the thermal stability under the same other conditions.

3. Good conductivity and thermal conductivity

Its conductivity is 100 times higher than that of ordinary nonmetallic ore, 5 times higher than that of stainless steel, and 3 times higher than that of carbon steel. Its thermal conductivity decreases with the increase of temperature and tends to be adiabatic at extremely high temperatures.

4. Plasticity

The toughness of molding graphite powder is very good, it can be connected to a very thin sheet.

5. High-temperature resistance

Carbon graphite powder has strong high-temperature resistance, melting point is 3850 ± 50 ℃, the boiling point is 4250 ℃. The strength of general materials will gradually decrease at high temperatures, but its strength will double that at room temperature.

6. Chemical stability

The chemical stability of graphite powder is very good, it can replace non-ferrous or ferrous metal materials, and is widely used as anti-corrosion structural materials.

Application of Graphite Powder

Because of its special properties, graphite oxide powder is a necessary mineral raw material for traditional industries and strategic emerging industries. It is widely used in various industries.

Graphite powder is used as a conductive material to make electrodes, brushes, carbon tubes, carbon rods, and TV picture tube coating in the electrical industry.

Graphite powder as refractory can be used to make carbon graphite crucible and steel making as a protective agent of steel ingot.

Graphite powder is used as wear-resistant lubricating material and lubricant and wear-resistant material in the machinery industry.

Graphite powder can be used as a mold and metallurgical material in metallurgical casting.

Graphite powder can also be widely used in the field of sealing and lubrication of industrial equipment joints in the chemical industry.

Natural Flake Graphite

Natural Flake Graphite Details

Details

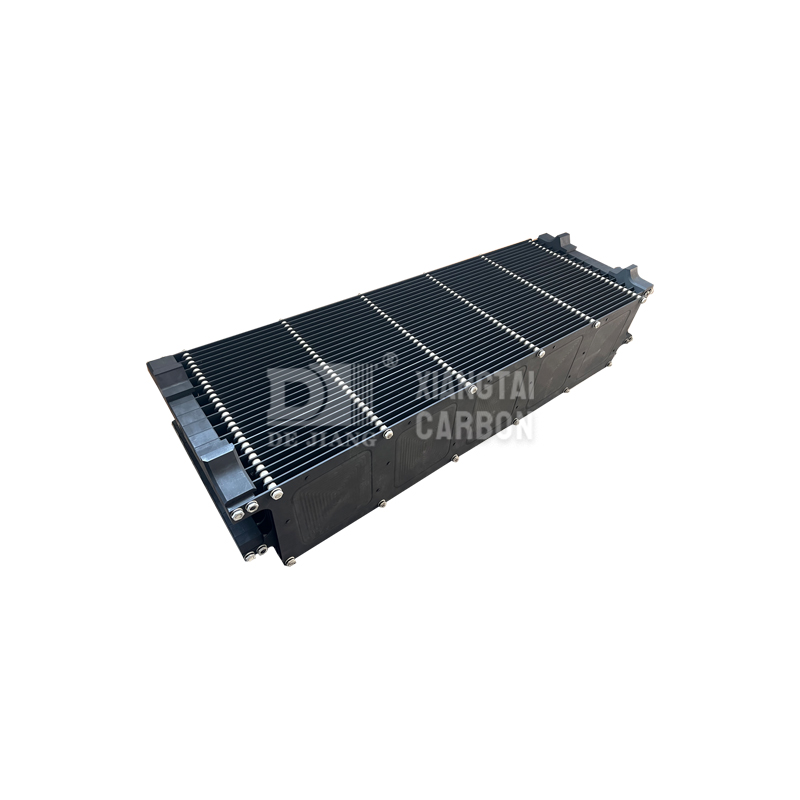

Recommended Products

Recommended Products